Are you a car enthusiast looking to upgrade your engine’s performance? One option you might consider is sleeving your engine block. But before you dive into this modification, it’s crucial to understand what it entails and how much it’ll cost you.

In this blog post, we’ll explore the world of engine block sleeving, answering some common questions like why engine blocks are not made of steel, whether you can sleeve a cracked cylinder, and how much it costs to sleeve an engine block. We’ll also touch on other engine-related topics like the different types of car engines, the advantages of rebuilding an engine, and the types of engines that exist.

So, if you’re ready to dive into the world of engine block sleeving and discover the cost implications, keep reading!

How Much Does It Cost to Sleeve an Engine Block

If you’re a car enthusiast or someone who loves tinkering with engines, you may have come across the term “sleeving an engine block.” But what exactly does it mean, and more importantly, how much will it cost you? Let’s dive into this rabbit hole and find out!

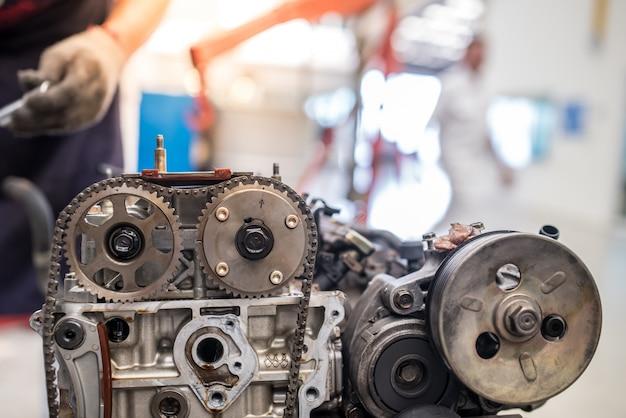

Understanding Engine Block Sleeving

Before we jump into the cost breakdown, let’s quickly cover the basics. Engine block sleeving is a process that involves fitting a new cylinder sleeve into the engine block. It’s typically done when the original cylinders are worn out, damaged, or if you’re planning to modify your engine for higher horsepower.

The Cost Breakdown

Now, let’s get to the part you’ve been eagerly waiting for – the cost! Keep in mind that these numbers are approximate and can vary depending on your location, the type of vehicle, and the specific circumstances. Without further ado, here’s a breakdown of the estimated costs involved in sleeving an engine block:

1. Cylinder Sleeves

The first significant cost you’ll encounter is for the cylinder sleeves themselves. On average, you can expect to pay anywhere between $200 to $600 per sleeve, depending on the material and quality. So, if your engine requires all four cylinder sleeves to be replaced, you’re looking at a ballpark price range of $800 to $2400 just for the sleeves. Ouch!

2. Machine Work and Labor

Sleeving an engine block is no walk in the park, and it’s a job best left to the professionals. The machine work and labor costs for this procedure can range from $1000 to $3000. It involves removing the engine block, disassembling it, honing the cylinders, installing the new sleeves, and reassembling everything back to its former glory.

3. Additional Parts and Services

Sometimes, unexpected surprises pop up when you’re knee-deep in engine block sleeving. You might need to replace other components like gaskets, seals, or even perform extra machining on the block for a proper fit. These additional parts and services can add anywhere between $500 to $1500 to your overall cost. So, be prepared for some minor financial detours along the way.

Sleeving an engine block is not for the faint of heart or the shallow of wallet. Depending on the complexity of the job, the type of vehicle, and the materials used, you can end up spending anywhere from $2500 to $7000 or more. However, keep in mind that these are rough estimates, and the final cost will depend on various factors.

So, before you embark on your engine-sleeving adventure, make sure you do your research, find a reputable shop, and have a clear understanding of the total expenses involved. It might not be cheap, but the end result—a rejuvenated and potentially more powerful engine—will bring a smile to your face and a rumble to your car that’ll turn heads on the street!

FAQ: How much does it cost to sleeve an engine block

Sleeving an engine block is a common practice among car enthusiasts and performance enthusiasts alike. It involves inserting a sleeve into the cylinder bore of an engine to increase its strength and durability, allowing for greater horsepower and performance. However, the cost of sleeving an engine block can vary depending on various factors. In this FAQ-style subsection, we’ll address some of the most frequently asked questions about the cost and process of sleeving an engine block.

What’s the most horsepower you can get in a car

Ah, the age-old quest for more horsepower! For a regular production car, the Bugatti Veyron Super Sport holds the record with a mind-blowing 1,479 horsepower. However, if we’re talking about custom-built or modified cars, the horsepower can reach truly unimaginable levels. Just remember, with great power comes the great responsibility of keeping your tires on the ground!

How much will it set me back to sleeve an engine block

The cost of sleeving an engine block can vary depending on several factors, such as the type of engine, the materials used, and the complexity of the job. On average, you can expect to pay anywhere from $1,500 to $4,000 for a professional engine sleeving service. However, keep in mind that these numbers are just rough estimates and can go higher depending on your specific requirements and the reputation of the shop you choose. It’s always a good idea to reach out to several reputable shops to get accurate quotes for your specific engine model.

Why aren’t engine blocks made of steel

Oh, if only engine blocks were made of steel, they would be unstoppable! But alas, steel is a bit too heavy for the job. Engine blocks are typically made from cast iron or aluminum alloys because these materials strike a good balance between strength, weight, and cost. Cast iron provides excellent durability and heat dissipation, making it ideal for heavy-duty applications, while aluminum alloys offer a lighter weight and better heat conductivity, which can improve fuel efficiency. So, while steel might be tough, it’s just not the right fit for the job when it comes to engine blocks.

Can you sleeve a cracked cylinder

Absolutely! Engine cylinder sleeves are specifically designed to address cracked, damaged, or worn-out cylinders. By inserting a sleeve into the cylinder bore, you can effectively restore the structural integrity of the cylinder and provide a smooth, durable surface for the piston to operate. So, if you have a cracked cylinder, don’t worry, sleeving it can bring it back to life!

Which type of car engine is considered the best

Ah, the eternal debate of car enthusiasts! The answer to this question largely depends on your preferences and requirements. Each type of car engine has its own unique characteristics and advantages. Some may prefer the raw power and rumble of a V8 engine, while others may appreciate the smooth performance and efficiency of a V6 or even a hybrid engine. It ultimately boils down to what you value most in a car: power, fuel efficiency, or a blend of both. The best engine for you is the one that puts a smile on your face every time you press the pedal!

Is it worth rebuilding an engine

Ah, the classic “should I stay or should I go” conundrum of engine rebuilding. Whether it’s worth it to rebuild an engine depends on a few factors, such as the overall condition of the engine, the cost of parts and labor, and the value of the vehicle. If the engine has significant damage or the cost of rebuilding is close to the value of the car itself, it may be more cost-effective to consider a replacement engine or even a new car. However, if the engine has sentimental value or you’re working on a classic car, the satisfaction of reviving an old engine can be priceless. So, weigh your options carefully and follow your heart (and your wallet)!

Can you bore just one cylinder

While it may seem odd to bore just one cylinder, it is actually a common practice in engine rebuilding. Sometimes, one or more cylinders may have excessive wear, damage, or unevenness compared to the others. In such cases, a professional engine builder may recommend boring only the affected cylinder(s) to bring them back to the correct specifications. This approach can help save time, money, and resources while ensuring optimal performance. So yes, don’t fret if only one cylinder needs a little extra attention—it’s all part of the engine rebuilding process!

What cars have a V16 engine

Ah, the elusive V16 engine—a true rarity in the automotive world! While V16 engines were more common in bygone eras, they have become extremely scarce today. One notable example of a car with a V16 engine is the iconic Cadillac Sixteen concept car, which made its debut in 2003. With its groundbreaking design and exceptional performance, the Cadillac Sixteen solidified its place in automotive history as a testament to the ingenuity and craftsmanship of American car manufacturers.

Is a V12 better than a V8

Ah, another vibrant debate in the realm of car enthusiasts! The answer, my friend, depends on your preferences and needs. V12 engines are known for their silky-smooth performance, refined power delivery, and symphonic exhaust notes. They often find their home in high-end luxury cars and supercars. On the other hand, V8 engines offer a punchy performance and a throaty growl that many car enthusiasts crave. They strike a balance between power and efficiency and are found in a wide range of vehicles, including muscle cars and sports sedans. So, whether a V12 or V8 is better is entirely up to you and the driving experience you desire!

What are the two types of engines

Ah, let’s dive into the wonderful world of engine variety! Generally, there are two main types of engines: internal combustion engines (ICE) and electric motors. Internal combustion engines are further divided into gasoline engines (also known as spark-ignition engines) and diesel engines (also known as compression-ignition engines). Gasoline engines are most common in passenger cars, while diesel engines are often found in heavy-duty trucks and some passenger cars. Electric motors, on the other hand, are gaining momentum in the automotive industry as the world shifts toward sustainable transportation options. So, whether you prefer the roar of an engine or the whisper of electrons, there’s an option for every type of driver out there!

What is the bottom half of the engine block called

Ah, we’ve reached the lower depths of the engine block! The bottom half of the engine block is known as the crankcase. It serves as the housing for the crankshaft, which converts the linear motion of the pistons into rotational motion. The crankcase, together with the cylinder block, forms the foundation of the engine, ensuring that all the moving parts are properly supported and lubricated. So, next time you’re peeking under the hood, don’t forget to give a nod to the crankcase—it’s the unsung hero that keeps your engine running smoothly!

Can you sleeve an aluminum block

Indeed you can, my friend! While it’s more common to sleeve cast iron engine blocks, you can also sleeve aluminum blocks. However, sleeving an aluminum block requires extra care and precision due to the softer nature of the material. Specialized equipment and techniques are used to maintain the integrity of the block while inserting the sleeve. So, if you have an aluminum block in need of some reinforcement, fear not—professional engine builders can work their magic and breathe new life into your block!

What typically mounts on top of the engine block

Ah, the crowning jewel of the engine block—meet the cylinder head! The cylinder head is the topmost part of the engine block and houses the intake and exhaust valves, spark plugs, and often the camshaft. It plays a crucial role in the combustion process, sealing the cylinders and directing the flow of gases in and out of the engine. The design and specifications of the cylinder head greatly influence the engine’s performance, efficiency, and power output. So, the next time you’re gazing at an engine block, remember to give a nod to the mighty cylinder head sitting on top!

What are the three main types of engines

Ah, let’s explore the trio of engine greatness! The three main types of engines are reciprocating engines, rotary engines, and electric motors. Reciprocating engines, which include the majority of engines used in vehicles, operate by converting linear motion into rotational motion through pistons and crankshafts. Rotary engines, also known as Wankel engines, feature a unique rotary design that uses a rotor instead of pistons. Electric motors, on the other hand, utilize magnetic fields to create motion and are central to electric and hybrid vehicles. So, whether you prefer the rhythmic dance of pistons, the elegant whirl of a rotor, or the futuristic silence of electric motion, the world of engines has something for everyone!

How much does it cost to bore an engine block

Ah, the sweet serenade of engine boring! The cost of boring an engine block can vary depending on various factors, including the size of the engine, the condition of the cylinders, and the precision required. Generally, you can expect to pay anywhere from $300 to $600 per cylinder for professional engine boring services. However, it’s worth noting that these are just ballpark figures, and the final cost may vary depending on the specific shop and your location. Always consult with reputable engine builders to get accurate quotes for your engine’s unique needs.

And there you have it, folks! We’ve explored some of the most frequently asked questions about the cost, process, and nuances of sleeving an engine block. Whether you’re a car enthusiast or just curious about the inner workings of these mechanical marvels, we hope this FAQ has piqued your interest and left you with a newfound appreciation for the world of engine modifications. Remember, when it comes to engine sleeving, it’s not just about the cost—it’s about unlocking the untamed power and potential within your car’s heart!