Lathe machines are often considered the “Father of all machines” due to their crucial role in shaping various materials with precision. These powerful tools are commonly used in workshops and manufacturing units for a wide range of applications, such as woodturning, metalworking, and glassblowing. By holding and rotating the workpiece, a lathe machine enables the cutting tools to shape and form the material into desired shapes and sizes.

In this blog post, we will explore the functions and advantages of lathe machines, as well as their limitations. We will also delve into the reasons why they are often referred to as the “Father of all machines” and shed light on the difference between turning and milling. Whether you are a DIY enthusiast or a professional in the machining industry, understanding the capabilities and limitations of lathe machines is essential for any project. So, let’s dive in and discover the world of lathe machines together!

Stay tuned as we provide insights, tips, and answers to the fascinating questions surrounding lathe machines. Let’s embark on a journey to unravel the secrets of this versatile tool and explore its significant contributions to precision machining.

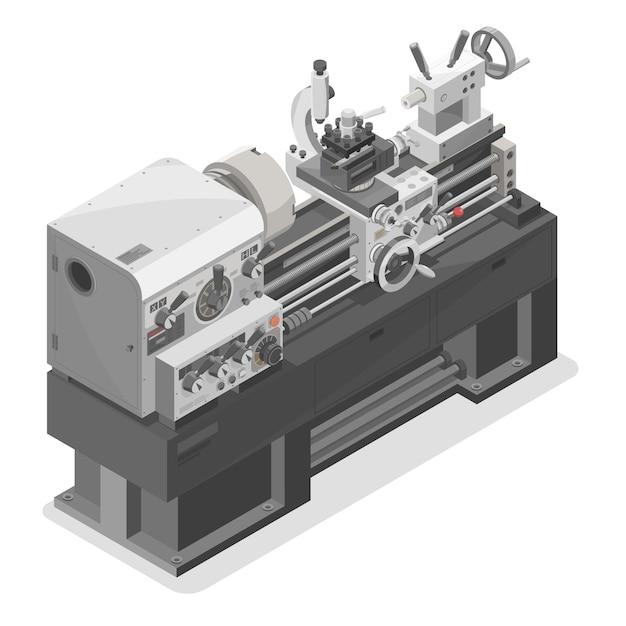

What is a Lathe Machine and the Functions of the Part?

Understanding the Lathe Machine: A Master of Spin

If you’ve ever wondered what a lathe machine is and what it does, get ready to have your mind spun with excitement (pun intended). A lathe machine is like a magician’s trick, turning a humble piece of material into a work of art. It’s a tool that has been around for centuries, standing the test of time like a wise old wizard.

The Basics: Turning and Spinning in Style

At its core, a lathe machine is all about spinning things around. Just imagine a merry-go-round, but instead of kids laughing and screaming, it’s metal or wood getting transformed. This magical contraption consists of several parts working in harmony to shape and mold materials with precision.

The Mighty Headstock: The Brain of the Operation

Meet the headstock, the commander-in-chief of the lathe machine. It holds the primary spindle, which grips the material, and rotates it at various speeds. Think of it as the muscle that brings life to the raw material, breathing creativity into every spin.

The Trusty Tailstock: Providing Balance and Support

While the headstock takes the spotlight, let’s not forget about the trusty sidekick – the tailstock. It works hand in hand with the headstock, providing balance and support to the material during shaping. It ensures that everything stays in place, preventing any wobbly mishaps.

The Versatile Tool Post: An Artist’s Arsenal

Enter the tool post, a handy contraption that carries cutting tools. This versatile hero gives the operator the power to shape the material, be it metal or wood, with precision and finesse. Picture a painter with a palette knife, sculpting a masterpiece stroke by stroke.

The Joy of Spinning: Functions of the Lathe Machine

Now that we’ve met the stars of the show, let’s dive into the functions that make the lathe machine such a valuable tool in the world of craftsmanship:

1. Turning: From Cylinder to Beauty

The primary function of a lathe machine is turning. It takes a cylindrical piece of material and transforms it into various shapes, be it round, tapered, or even contoured. It’s like having a magic wand that effortlessly brings any idea to life.

2. Drilling: Boring Holes with Ease

With the help of specialized attachments, a lathe machine has the power to drill holes with precision. It ensures that holes are perfectly centered and of the right dimensions, like a marksman hitting a bullseye.

3. Knurling: Adding Grip and Perfection

If you’ve ever marveled at the intricately patterned handles on tools or machinery, you have the lathe machine to thank. Through the process of knurling, it adds ridges to cylindrical surfaces, improving grip and adding an aesthetic touch.

4. Facing: A Smooth and Perfect Finish

No one likes rough edges, right? Well, the lathe machine has got you covered. Facing is the process of creating a flat, smooth surface on the end of the material. It ensures that everything looks polished and professional – just like a shiny new penny.

5. Parting: Where Materials Go Their Separate Ways

Sometimes, materials need a little separation. That’s where the lathe machine comes in with its parting function. It brings the material to the brink of division, cutting it cleanly and precisely, ensuring a clean break-up without any emotional baggage.

Recap: The Lathe Machine Unveiled

So, there you have it! The lathe machine, a true master of spin, with its enchanting ability to shape and mold materials into beautiful creations. From turning and drilling to knurling, facing, and parting, this versatile tool is a magician’s ally, conjuring wonders with every revolution. Whether you’re a seasoned craftsman or just starting your creative journey, the lathe machine is sure to captivate you with its endless possibilities. Get ready to spin your way into artistic greatness!

Now that we’ve revealed the secrets of the lathe machine and its functions, it’s time to roll up those sleeves and unleash your inner creativity. Let the lathe machine be your guiding force as you embark on your own magical journey of craftsmanship. Remember, with the power of spin on your side, the possibilities are boundless!

FAQ: What is a Lathe Machine and the Functions of the Part?

Why Is Lathe Called the Father of All Machines

Lathe machine is often referred to as the “Father of all machines” because of its versatile nature and its ability to produce an array of intricate and complex parts. Just like a father who plays a crucial role in a family, the lathe machine is foundational to the manufacturing industry, enabling the creation of various components that serve as building blocks for countless other machines and products. Its importance and significance cannot be understated.

Is the Lathe Machine Used to Hold the Job

Absolutely! The lathe machine is indeed used to hold the job in place. Think of it as a trusty pair of hands that firmly grip the workpiece, allowing precision and accuracy during the machining process. This ensures that the job remains stable and secure, preventing any unwanted movement that could result in errors or imperfections. So rest assured, your job is in good hands with a lathe machine!

What Exactly Is a Lathe Machine and What Are Its Functions

Ah, the mighty lathe machine – a true workhorse in the world of machining. Essentially, a lathe machine is a tool that spins a workpiece on its axis, enabling various operations such as cutting, drilling, sanding, or shaping. It consists of several parts, each with its own unique function. Let’s break it down:

-

Bed: The sturdy foundation of the lathe machine, providing stability and support to the other components.

-

Headstock: The powerhouse that houses the main spindle, chuck, and other vital components, responsible for rotating the workpiece.

-

Tailstock: The tailstock acts as a counterpoint to the headstock, providing additional support and stability to the workpiece.

-

Carriage: This movable component holds the cutting tool and can be adjusted along the length of the lathe, allowing precise machining processes.

-

Chuck: The chuck securely grips the workpiece, allowing rotational movement and facilitating the machining operations.

-

Tool Rest: This serves as a platform for the cutting tools, ensuring proper alignment and stability during shaping and cutting processes.

-

Lead Screw: The lead screw is responsible for the smooth and precise movement of the carriage along the lathe’s axis.

So you see, the lathe machine is a master of many functions, capable of transforming raw materials into impressive finished products through its various parts working in harmony.

What Are the Drawbacks of Using a Lathe Machine

While the lathe machine is indeed a versatile and valuable tool, it does come with a few limitations. Here are some drawbacks to keep in mind:

-

Limited Shape Complexity: While the lathe machine is fantastic at creating cylindrical shapes, it can be challenging to produce intricate and complex designs.

-

Size Restrictions: The size of the workpiece is limited by the dimensions of the lathe machine. Large or bulky items may pose a challenge.

-

Time-Consuming Setups: Preparing the lathe machine for a specific job can be time-consuming, requiring meticulous adjustments and precise alignments.

-

Operator Skill: Successfully operating a lathe machine calls for a certain level of skill and experience. Inexperienced operators may face difficulties achieving desired results.

Despite these minor drawbacks, the lathe machine remains an invaluable tool in the manufacturing industry.

Why is Some Lathe Machines Called Turret Lathes

Ah, the intriguing world of machine nomenclature! A turret lathe is so named because of its unique, turret-like structure. Picture a cylindrical tower, and inside it, a series of tool holders arranged at various positions. This enables swift and seamless tool changes, allowing for increased efficiency and versatility in machining operations. So, next time you come across the term “turret lathe,” remember that it’s all about that handy dandy tool-holding turret!

What’s the Difference Between Turning and Milling

Turning and milling are like the dynamic duo of machining, each with its own unique superpowers. Here’s the lowdown on the two:

Turning: Think of a lathe machine in action – rotating a workpiece as a sharp cutting tool engages with it. This process is called turning. It is primarily used for cylindrical shapes and involves removing material from a rotating workpiece to create symmetry and desired dimensions.

Milling: In contrast to turning, milling involves the movement of a cutting tool in multiple directions to achieve various desired shapes and features. Instead of the workpiece rotating, it remains stationary as the cutting tool moves along different axes. Milling is perfect for creating complex shapes, slots, and grooves.

So, in a nutshell, turning focuses on rotating the workpiece, while milling involves moving the tool around. Together, they form a formidable duo, catering to different machining needs.

And there you have it, all your burning questions about lathe machines and their functions answered!