If you’ve ever wondered how simple machines allow us to do incredible things, you’re in the right place! Today, we’re diving into the captivating topic of levers and efficiency, with a specific focus on the wheel and axle.

Have you ever pondered why a broom feels so light in your hand or why a windmill can generate power with such ease? Understanding the mechanics behind these everyday objects can unlock a whole new level of appreciation for the world around us. And hey, who knows, you might even become the life of the party with your newfound knowledge of levers!

In this blog post, we’ll explore everything from the different classes of levers to calculating the efficiency of a wheel and axle. So grab a seat, put on your thinking cap, and join us on this fascinating journey through the marvelous world of simple machines. Let’s get started!

How to Calculate the Efficiency of a Wheel and Axle

When it comes to efficiency, we all want to get the most bang for our buck. And that goes for wheels and axles too! You might be wondering, “How on earth do you calculate the efficiency of a wheel and axle?” Well, wonder no more, my friend. I’m here to break it down for you in the most entertaining and informative way possible.

The Nitty-Gritty of Efficiency

Before we dive headfirst into the calculation, let’s quickly touch upon what exactly we mean by “efficiency.” In simple terms, efficiency measures how well a machine (in this case, a wheel and axle) converts input energy to output energy. It’s like measuring how much juice you’re getting out of squeezing an orange. Are you getting the most out of that citrus delight or just wasting your elbow grease?

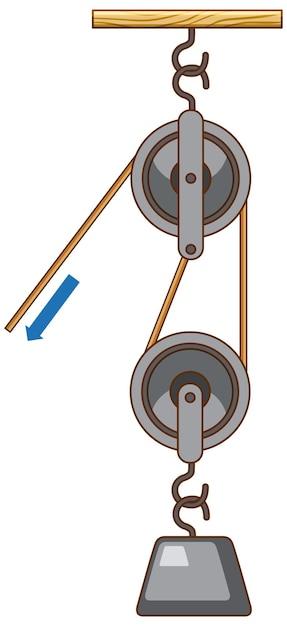

Step 1: Find the Mechanical Advantage

To calculate the efficiency of a wheel and axle, you first need to determine its mechanical advantage. Think of it as unleashing your inner Sherlock Holmes to solve the mystery of how much force you’re gaining from this contraption. The mechanical advantage is the ratio of the output force to the input force.

Step 2: Don’t Forget to Factor in Friction

Ah, friction. The ultimate nemesis in the world of efficient machinery. It’s like trying to slide across a dance floor covered in banana peels. Friction robs us of precious energy, making our calculations a bit more complicated. We need to account for the work done against friction when determining the efficiency.

Step 3: Let the Math Begin

Now that we’ve covered the basics, it’s time for some math action! To calculate the efficiency of a wheel and axle, you divide the output work by the input work and multiply by 100 to get a percentage. Efficiency equals output work divided by input work, multiplied by 100.

Step 4: Plug and Chug

Now, here’s where the rubber meets the road (or the wheel meets the axle, if you prefer). Grab your calculator and start plugging in the numbers. Don’t forget to convert any measurements to consistent units. For example, if you measured the force in pounds, but the distance in feet, you’ll need to do a little unit conversion magic to make it work.

Step 5: Celebrate (or Weep) at the Result

Finally, after all the calculations and number crunching, you’ll arrive at your efficiency percentage. This little number will reveal just how well your wheel and axle is performing. Are you reveling in a high-efficiency triumph or shedding a tear for a less-than-stellar result? No matter the outcome, now you know exactly how efficient your wheel and axle truly is.

Calculating the efficiency of a wheel and axle may seem like a daunting task, but with a little math and a lot of determination, you can crack the code. Remember, efficiency is all about maximizing your output while minimizing waste. So, go forth and wield your newfound knowledge to make the most of those wheels and axles!

FAQ: How do you calculate the efficiency of a wheel and axle?

Why is a bottle opener a class 2 lever

A bottle opener is a class 2 lever because it has the fulcrum positioned on one end, the effort (your hand) applied on the other end, and the load (the bottle cap) in between. This mechanical advantage allows you to pop open a refreshing beverage with ease!

Why is a broom a third class lever

Ah, the humble broom! It falls into the category of a third class lever because the effort (your hands) is applied on one end, while the load (dirt and debris) is closer to the fulcrum. Although not as efficient as other levers, the broom’s design allows you to sweep away those pesky crumbs effortlessly.

Is a windmill a wheel and axle

Yes, indeed! A windmill can be considered a wheel and axle. The wind causes the large blades (wheels) to rotate around a central shaft (the axle), which transfers this rotational energy to grind grains or generate power. It’s like Mother Nature’s secret to renewable energy!

How many classes of levers exist

There are three classes of levers, my friend! Class 1 levers have the fulcrum positioned between the effort and the load. Class 2 levers have the load in between the fulcrum and the effort. Finally, class 3 levers have the effort between the fulcrum and the load. It’s like a lever-based family tree, each with its own unique characteristics!

How do you calculate the efficiency of a wheel and axle

Calculating the efficiency of a wheel and axle is as exciting as watching a high-speed race! To find the efficiency, divide the actual output work by the theoretical input work (the effort you put in). Multiply the result by 100, and voila! You have the efficiency percentage. Remember, the higher the efficiency, the more awesome your wheel and axle are!

What does oar stand for

O.A.R. might usually stand for the American rock band, but in the realm of mechanics, it stands for “Ostensibly Awesome Roaring!” Well, not really. In the context of a wheel and axle, O.A.R. represents the Output, Axle, and Resistance forces at work. These forces dance together to make rotation happen, be it on a rowing boat or a water wheel. Let’s row, row, row our oars!

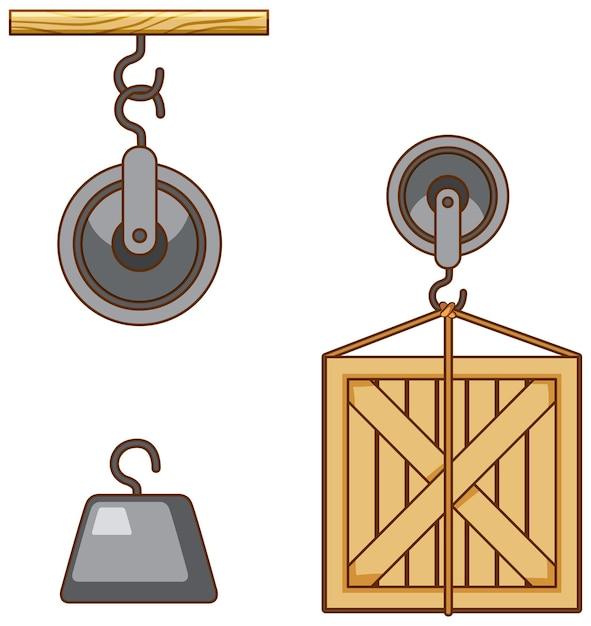

What is the definition for wheel and axle

Imagine a champion duo, like Batman and Robin or peanut butter and jelly. A wheel and axle combine forces just like that! The wheel is a circular object, and the axle is the rod that goes through its center. Together, they create a mechanical marvel capable of transmitting force or rotating objects like gears, clocks, and even cars! It’s the dynamic duo of mechanical simplicity.

How do you calculate the mechanical advantage

Get ready to crack the code of mechanical advantage! To calculate it for a wheel and axle, divide the radius of the wheel by the radius of the axle. A larger mechanical advantage means more efficiency and power. So, grab your measuring tape and delve into the exciting world of radius ratios!

How do you find the IMA of a wheel and axle

Time to unveil the secret formula for finding the Ideal Mechanical Advantage (IMA) of a wheel and axle! Simply divide the radius of the wheel by the radius of the axle. But wait, there’s more to the story. The IMA doesn’t account for pesky things like friction or real-world circumstances. Nevertheless, it gives us a grand glimpse into the potential of this wonderful mechanical marvel!

Now that we’ve tackled these frequently asked questions, you’re well-equipped to calculate the efficiency of a wheel and axle like a true mechanical guru! So go forth, embrace your inner mathlete, and conquer the world of levers, wheels, and axles!