Have you ever experienced issues with your vehicle’s crankshaft sensor? If so, you’re not alone. The crankshaft sensor plays a vital role in the proper functioning of an engine, but sometimes, it can encounter problems. One common question that arises is whether there is a fuse for the crankshaft sensor. In this blog post, we’ll delve into this topic and provide you with all the essential information you need to know.

In addition to exploring the existence of a fuse for the crankshaft sensor, we’ll also touch upon related questions. For instance, we’ll delve into the process of calibrating a crank sensor and the consequences of a malfunctioning cam sensor. By the end, you’ll have a comprehensive understanding of these crucial components and how they impact the overall performance of your vehicle.

So, if you’re ready to dive deeper into the world of crankshaft sensors, calibration methods, and the potential issues associated with cam sensors, let’s get started!

Is there a fuse for the crankshaft sensor

The crankshaft sensor is a critical component in a car’s engine, responsible for monitoring the position and rotational speed of the crankshaft. If the sensor fails, it can lead to various engine problems, including misfires and stalling. But what about a fuse? Could a blown fuse be the culprit behind a malfunctioning crankshaft sensor? Let’s dive into this topic and find out!

The Mystery of the Crankshaft Sensor Fuse

When troubleshooting engine issues, it’s common to wonder if there’s a fuse specifically dedicated to the crankshaft sensor. After all, a blown fuse could be an easy fix compared to replacing the sensor itself. Unfortunately, there is no fuse specifically assigned to the crankshaft sensor. Bummer, right? But don’t fret just yet; there’s more to the story!

The Butterfly Effect: The Role of Other Fuses

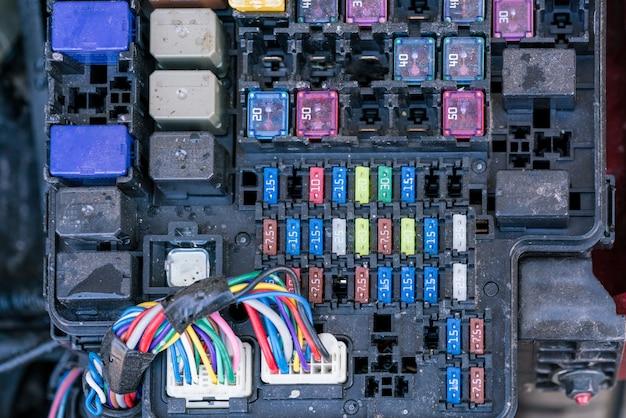

While there might not be a fuse exclusively for the crankshaft sensor, that doesn’t mean other fuses can’t play a role in its functionality. Several fuses in your car’s fuse box can indirectly affect the crankshaft sensor. For instance, a blown fuse related to the engine control unit (ECU) or the ignition system could interfere with the sensor’s operation.

A Blessing in Disguise: The Diagnostic Port

To further complicate matters, modern cars often rely on complex engine management systems, making it challenging to pinpoint specific sensor failures. Fortunately, car manufacturers anticipated this and provided us with a lifeline called the onboard diagnostics (OBD) port. By connecting a diagnostic tool to this port, you can retrieve valuable error codes and data, helping identify possible issues with the crankshaft sensor or related components.

The Technological Wizardry: Wiring and Grounding

Before resorting to fuse-related concerns, Double-check the wiring and grounding around your crankshaft sensor. A loose wire or a poor ground connection can wreak havoc on sensor signals and cause erratic behavior. So, it’s wise to inspect the connections before delving into the realms of fuses.

Pro Tips: When Fuses Can Save the Day

Although the crankshaft sensor itself doesn’t have a dedicated fuse, there are situations where a blown fuse can indeed impact its operation. For example, if the crankshaft sensor circuit shares a fuse with other critical engine components and that fuse blows, it can lead to sensor malfunctions. In such cases, you might find yourself replacing the fuse and, with any luck, resolving the issue.

Conclusion: The Fuse-less Sensor Saga

In the quest for a specific fuse for the crankshaft sensor, we’ve unraveled a tale of intrigue and complexity. While there isn’t an exclusive fuse for this sensor, other fuses and connection issues can affect its functionality indirectly. So, don’t overlook the power of correct wiring, inspecting ground connections, and utilizing diagnostic tools through the OBD port. And remember, when all else fails, consulting a professional mechanic is always a wise decision.

Now that you’re armed with knowledge about the crankshaft sensor and fuses, you can navigate engine troubles like a seasoned detective. So, the next time someone asks, “Is there a fuse for the crankshaft sensor?” You can confidently reply, “No, but let me tell you all the other fascinating aspects of this subject!” Keep those engines running smoothly and fuse on!

FAQ: Is there a fuse for the crankshaft sensor

How to calibrate a crank sensor

The process of calibrating a crank sensor can vary depending on the specific vehicle make and model. However, here are some general steps you can follow:

- Determine the location of the crank sensor – It is typically located near the crankshaft or in the engine block.

- Disconnect the battery – This is an important safety precaution to avoid any electrical mishaps.

- Remove any components blocking access to the crank sensor – In some cases, you may need to remove other parts to gain proper access to the sensor.

- Locate the adjusting screw or bolt – This is used to adjust the position of the sensor.

- Use a multimeter – Connect the multimeter to the sensor’s electrical connector to measure the voltage or resistance readings.

- Adjust the sensor – Rotate the adjusting screw or bolt to align the sensor with the crankshaft.

- Check the readings – Monitor the readings on the multimeter and make adjustments as necessary until the desired values are reached.

- Secure the sensor – Once properly aligned and calibrated, tighten the adjusting screw or bolt to secure the sensor in place.

- Reassemble any removed components and reconnect the battery.

Is there a fuse for the crankshaft sensor

No, there is usually no dedicated fuse for the crankshaft sensor in most vehicles. The crankshaft sensor, also known as the engine position sensor, is typically powered by the vehicle’s electrical system. It relies on the electrical signals generated by the rotating crankshaft to provide crucial information to the engine control unit (ECU). Therefore, it is not directly protected by a separate fuse. However, it’s important to note that if there is an issue with the electrical system, such as a blown fuse or a malfunctioning wiring harness, it can indirectly affect the performance of the crankshaft sensor.

What happens when the cam sensor goes bad

When a cam sensor goes bad, it can lead to various issues with your vehicle’s performance. Here are some common signs indicating a faulty cam sensor:

Check Engine Light (CEL) Illumination

A malfunctioning cam sensor can trigger the check engine light to illuminate on your dashboard. The ECU detects irregularities in the camshaft position and alerts you to a potential problem.

Engine Misfires or Stalling

A bad cam sensor can disrupt the accurate timing of the engine’s valves, causing misfires or even stalling. This can result in a sluggish or unresponsive engine, reduced fuel efficiency, and poor acceleration.

Difficulty Starting the Engine

The cam sensor helps the ECU determine the correct timing for fuel injection. If the sensor is faulty, it may send incorrect signals, leading to difficulties in starting the engine, such as prolonged cranking or failure to start.

Loss of Power

A failing cam sensor can cause the engine to lose power, resulting in reduced performance. You may experience a lack of responsiveness when accelerating or a decrease in overall horsepower.

Increased Emissions

A malfunctioning cam sensor can disrupt the precise synchronization between the camshaft and the engine control unit. This can lead to increased emissions, potentially causing your vehicle to fail emissions tests.

Conclusion

Regular maintenance and prompt attention to any issues with your vehicle’s sensors, including the crankshaft and camshaft sensors, are essential to ensure optimal performance. If you suspect a problem with either of these sensors, it’s advisable to consult a qualified mechanic or refer to your vehicle’s manufacturer guidelines for diagnostics and proper resolution. Remember, addressing issues promptly can prevent further damage and help you avoid costly repairs.