Have you ever wondered how to reinforce Styrofoam to make it stronger and more resilient? Whether you’re working on a DIY project or simply want to protect fragile items, finding the right techniques to reinforce Styrofoam can be crucial. In this blog post, we’ll explore various methods and materials that can help you reinforce Styrofoam and create a durable structure that stands the test of time.

But first, let’s address some common concerns. When it comes to reinforcing Styrofoam, questions often arise about the safety of certain materials, such as epoxy resin. People wonder if epoxy resin can be harmful or if it emits toxic fumes. We’ll delve into this topic and provide you with all the necessary information to keep yourself and your environment safe.

So, if you’ve ever pondered questions like “Can I use resin on Styrofoam?” or “How do I fiberglass over Styrofoam?”, this blog post is for you. By the end of this guide, you’ll have all the insights you need to successfully reinforce Styrofoam and create a solid foundation for your projects.

How to Reinforce Styrofoam: Unleash Its Inner Strength!

Light as a Feather, Strong as Hulk: Reinforcing Styrofoam Like a Pro

Ah, Styrofoam, the lightweight superhero of packaging materials! While it may protect our precious purchases from the perils of shipping, it sometimes crumbles under pressure faster than a sitcom dad facing a teenage daughter’s questioning gaze. But fear not, dear reader, for I am here to reveal the secrets of reinforcing Styrofoam, transforming it into a fortress of strength! So gather ’round and prepare to witness the incredible metamorphosis of this soft, squishy material.

1. A Solid Foundation: Fill the Void

Before we can reinforce Styrofoam, we must address its greatest weakness—the empty void within. Often, Styrofoam’s fragility stems from its hollow nature. But worry not, for we hold the key to stability! Simply fill the void within Styrofoam with a filler substance like epoxy or expanding foam. This will lend strength and support to those brittle walls, making them as resilient as a marathon runner on a sugar high.

2. Fiber Up: Wrap It Like a Burrito!

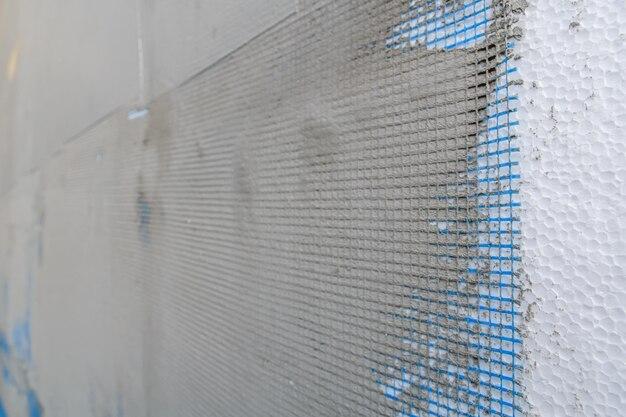

Picture this: you’re holding an ice cream cone, about to take a delicious lick, and disaster strikes—the ice cream falls flat on the ground. Well, my friend, we can’t let that happen to our beloved Styrofoam! Wrap it up, like a burrito filled with strength-inducing fibers! Encase your Styrofoam creation with materials such as fiberglass or carbon fiber. These reinforcements act as an invisible suit of armor, shielding it from impacts that would send ordinary Styrofoam into a frenzy of crumbles.

3. Glue for Glory: Bond It Together

Sometimes, Styrofoam needs a little help from its friends. That’s where trusty adhesives come into play. When reinforcing larger Styrofoam structures or joining multiple pieces together, reach for strong bonding agents like polyurethane adhesive or construction adhesive. These adhesives create an unbreakable bond, making your reinforced Styrofoam creation as solid as a rock (well, maybe slightly less heavy).

4. Layer by Layer: Sandwich with Strength

Imagine building a house with only one brick—rather precarious, wouldn’t you say? The same principle applies to reinforcing Styrofoam. By layering it with additional materials like plywood or metal sheets, you’ll create a powerful sandwich of support. These layers work together like a team of specialists, each contributing its unique strength to the overall structure. So stack it up, my friend, and watch as Styrofoam goes from wobbly lightweight to unyielding force!

5. Paint It On: The Power of Protective Coatings

When reinforcing Styrofoam, we can’t underestimate the importance of a good coat of paint! Not just any paint, mind you, but a special kind that offers protection and strength. Look for coatings such as high-density polyurethane or epoxy paint. These coatings not only add a splash of color but also provide a tough outer shell, making your Styrofoam masterpiece resistant to cracks, chips, and the occasional homeroom bully.

6. Fortify with Fabric: Wrap It Up and Say Goodbye to Weakness

If you want to take your Styrofoam reinforcement game to the next level, it’s time to welcome a textile ally into the mix. Yes, my friends, fabric can be a powerful partner in your quest for Styrofoam strength! By wrapping your Styrofoam creation with materials like fiberglass cloth or Kevlar fabric, you’ll give it a whole new level of fortification. It’s like dressing your fragile Styrofoam in a suit of armor—your very own DIY knight in shining Styrofoam!

Unleash the Beast Within!

With these mighty techniques at your disposal, you now possess the power to reinforce Styrofoam and transform it from a delicate daisy into a battle-hardened warrior. So, go forth, my intrepid creators, and let your imagination run wild. Whether you’re crafting props, architectural models, or even a cosplay masterpiece, remember that Styrofoam is no longer a fragile underdog—it’s a force to be reckoned with!

FAQ: How to Reinforce Styrofoam

Can epoxy resin harm you

Epoxy resin in itself is not deadly, but it can pose health risks if not handled properly. The chemicals in resin can emit harmful fumes and cause irritation to the skin, eyes, and respiratory system. It’s essential to take proper safety precautions and work in a well-ventilated area when using epoxy resin.

What happens if you use too much hardener with resin

If you add an excessive amount of hardener to epoxy resin, it can lead to a variety of issues. Firstly, the resin may not cure properly, remaining soft and sticky. Additionally, the excess heat generated during the curing process can cause the resin to bubble or crack. It’s vital to follow the instructions carefully and use the correct resin-hardener ratio for optimal results.

Why should you be cautious while working with resin

Resin can be hazardous due to its toxic properties and the potential for skin and respiratory irritation. It’s important to wear protective clothing, gloves, and a mask while working with resin to minimize the risks. Additionally, be mindful of the flammability of the materials and ensure proper ventilation in your workspace.

Is there a more cost-effective alternative to epoxy resin

Yes, there are cheaper alternatives to epoxy resin, particularly for reinforcing Styrofoam. One such alternative is polyurethane foam adhesive, which can effectively bond and reinforce Styrofoam while being more budget-friendly. However, it’s essential to choose the right adhesive based on your specific needs and the intended application.

Can you mix resin in a glass container

Yes, you can absolutely mix resin in a glass cup. Glass containers are an excellent choice for mixing resin as they are non-reactive and easy to clean. Just ensure that the glass cup is free from any contaminants or residue that could affect the curing process.

Can I use resin to reinforce Styrofoam

Certainly! Epoxy resin is a popular choice to reinforce Styrofoam due to its strong adhesive properties. By applying a layer of resin on the surface of Styrofoam, you can significantly enhance its durability and strength. This protective layer also helps to prevent chipping and damage.

How do you strengthen Styrofoam with resin

To reinforce Styrofoam using epoxy resin, follow these steps:

- Prepare the Styrofoam surface by cleaning it thoroughly and removing any dirt or debris.

- Apply a thin layer of resin evenly over the Styrofoam using a brush or roller.

- Allow the resin to cure for the recommended time to achieve maximum bonding and reinforcement.

- If desired, repeat the process to create additional layers for added strength and durability.

Can I fiberglass over Styrofoam

Yes, you can fiberglass over Styrofoam. Fiberglassing is a technique where a layer of fiberglass cloth or mat is applied to the surface of Styrofoam, creating a strong and rigid shell. It’s crucial to use the appropriate resin and fiberglass materials designed for this purpose, as they adhere well to Styrofoam and provide excellent reinforcement.

What is the safest resin to use

When it comes to safety, it’s important to choose resins that have low toxicity and emit fewer fumes during the curing process. One such option is bio-based epoxy resin, often made from renewable resources. These resins tend to have reduced volatile organic compounds (VOCs) and are considered safer for both the environment and human health.

Can resin be measured by weight instead of volume

Yes, resin can be measured by weight instead of volume. In fact, measuring resin and hardener by weight is often preferred for more accurate results. Using a digital scale, simply weigh the required amount of resin and hardener based on the ratio specified by the manufacturer. This method ensures precise measurements and helps achieve the desired resin curing properties.

What are some other coatings for Styrofoam

Apart from resin, there are various coatings you can use to protect and enhance Styrofoam. Some common options include acrylic paint, latex paint, spray paint, and even specialized foam coatings. These coatings provide a decorative finish, seal the surface, and offer protection against moisture and damage.

How long does the epoxy smell last

The duration of the epoxy smell can vary depending on factors such as ventilation and the type of epoxy used. Generally, the strong odor from uncured epoxy resin can last for a few days to a couple of weeks. Ensuring proper ventilation and allowing the resin to cure thoroughly can help accelerate the dissipation of the smell.

Can resin fumes be harmful

Yes, resin fumes can be harmful if inhaled in high concentrations and for extended periods. The fumes can cause respiratory irritation, headaches, dizziness, and nausea. Always work in a well-ventilated area, wear a respirator or mask specifically designed for organic vapors, and take regular breaks to minimize exposure to resin fumes.

Take the Reinforcement Leap!

Reinforcing Styrofoam with epoxy resin or fiberglass can provide immense strength and durability to your projects. However, it’s crucial to prioritize safety by following the necessary precautions and using the correct materials. Whether you opt for resin or fiberglass, the key is to have fun, unleash your creativity, and create something awesome! Happy reinforcing!